What About Roller Bearings

In A Big Bike Motor?

Regarding Harley Davidson motorcycles using roller bearings in their internal engine design, Amsoil synthetic oils are recommended for these applications. The assumption that synthetic motor oils are too "slippery" and cause roller bearing surfaces to slide instead of roll properly is not true.

Harley Davidson has never been able to provide a valid empirical explanation for their statements about synthetics. In fact, they have been stating this fallacy for quite some time without ever providing evidence that it really occurs.

Eaton-Fuller manufactures and designs transmissions for large trucks and industrial equipment. Nearly all of their transmissions contain roller bearings. If Harley Davidson's statement was true, why does Eaton-Fuller recommend synthetics to be used in their transmissions instead of petroleum based oils? It is because Eaton-Fuller has found that synthetic lubricants provide enhanced wear protection, wider operating temperatures, and other beneficial properties typical petroleum based lubricants cannot provide.

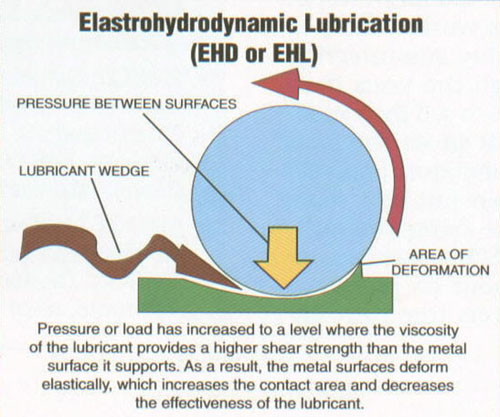

If an oil required for this application needs to allow friction to make these roller bearing elements operate correctly, then there is no doubt that other components in the engine will not be sufficiently protected. Besides, it is not entirely the frictional characteristics of the lubricant that permits rolling elements to operate effectively under normal conditions. Elastohydrodynamic lubrication (EHD) is the lubrication process typically generated in gear mechanisms and roller bearings. It is characterized by the occurrence of two phenomena:

- The metal deforms elastically under load, and recovers original profile exactly when the load is released. This effectively results in the apparent contact area between the opposing surfaces, and a reduction of the load per unit of bearing area.

- The high pressures generated in the oil film lead to an effective increase in viscosity. Fluids in general have positive viscosity/pressure coefficients and for synthetic oils, the increase is nominal. The first effect increases the surface area of the thin film of oil present between the opposed surfaces, and thereby reduces the stress within the oil. The second effect reduces the tendency for this oil to be squeezed out by the pressure between surfaces and forms a wedge of oil film to protect the rolling surfaces and maintain sufficient internal pressures to prevent slipping or sliding. Please use the enclosed diagram and descriptions of the three basic types of lubrication as reference.

Amsoil's excellent lubricity and film strength will not cause these bearings to fail; in fact, our oil helps to insure that all engine components will be protected against even the most severe operating conditions.

Elastohydrodynamic Lubrication (EHD or EHL) - Condition in which surfaces of rolling elements of high speed and high load components are either completely, or in part, separated by a very thin lubricant film. Mating parts deform elastically, due to incompressibility of the lubricant film under very high pressure and, therefore, trap or create a wedge of lubricant between them. This is similar to "hydroplaning" that cars exhibit on wet roads.

Please note the illustration below:

More Amsoil News & Technical Articles On The Amsoil Corporate Website